Hems are folded-again edges on sheet metal pieces, that may be opened or shut. In some cases, joining two hems also functions as fasteners. Bend sheet metal with ensuring the subsequent standards;

Sheet metal bending solutions are equivalent in that their stop intention is to transform metal constructions into the specified forms. Nonetheless, they vary in operation.

Normal calibration of the press brake’s stroke measurement system is suggested to make certain precise and consistent benefits.

High-quality Check: Last of all, every bent piece undergoes a thorough inspection to make certain it fulfills all the required angles and dimensions.

This capability is particularly very important for intricate sections with a number of bends or when restricted tolerances are essential. Operators can utilize the goniometer to:

This complex electrical architecture is elementary to acquiring the superior accuracy, repeatability, and performance demanded in present day sheet metal fabrication procedures.

R Axis: This axis facilitates vertical adjustment of the back gauge cross-bar, guaranteeing good contact involving the sheet metal and back gauges across several die heights.

Method situation holes must be established on bending parts to ensure the sheet metal’s specific positioning from the die. This might get rid of the sheet metal going in the course of the bending system and be certain specific outcomes across several sheet metals.

When deciding upon a goniometer for press brake applications, factors which include measurement vary, resolution, and magnetic energy really should be deemed to be sure compatibility with the precise bending tasks and working surroundings.

Advanced press brakes may also combine features like computerized tool changers, robotic product managing systems, and authentic-time bend angle measurement for Increased productivity and high quality control.

Reduced Set up Time: Operators can swiftly change among different punch profiles devoid of in depth downtime, enabling for more successful output scheduling.

We only use examined, marketplace normal and long run proof parts. Finally we guarantee the best quality by retaining our generation and assembly in-residence and applying world-renowned Swedish production expectations.

Advanced electronic goniometers frequently feature Liquid crystal display shows for simple studying and may be built-in with press brake Management systems for automated angle verification and adjustment.

X Axis: This axis determines the bend depth, defined as the gap between the back again gauges and the middle of your die. The cross-bar supporting the back gauges traverses along the check here X axis, transferring toward or away from the Y axis to obtain the specified bend depth.

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Monica Lewinsky Then & Now!

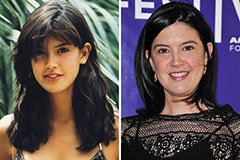

Monica Lewinsky Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!